Buying an OCA machine is a big step for anyone serious about mobile phone repair. In India, screen damage is one of the most common smartphone problems. From Android devices to iPhones, customers prefer glass-only repair when possible because it saves money and keeps the original display quality.

But choosing the wrong OCA laminating machine can waste your investment, slow your work, and damage displays. This OCA machine buying guide explains everything, based on real workshop experience and common industry practices in India.

If you are a beginner, repair shop owner, or planning to upgrade your setup, this article will help you make the right buying decision.

A good machine does not make you skilled, but the wrong machine can block your growth.

What Is an OCA Machine?

An OCA machine is used for glass-only screen repair. It helps replace the broken front glass while keeping the original LCD or AMOLED panel safe.

An OCA machine is also commonly known as an OCA laminating machine, glass laminator, screen lamination machine, or display bonding machine in the mobile phone repair industry. In everyday repair language, the display itself is also called an LCD, screen, combo, or folder, depending on the region.

OCA means Optical Clear Adhesive. This adhesive bonds the new glass to the display panel without bubbles or dust.

In simple words, the machine:

- Laminates new glass

- Uses vacuum and pressure

- Keeps the display clear and responsive

This process is used when only the front glass is broken, not the full screen or combo.

When Do You Actually Need an OCA Machine?

An OCA machine is useful only in specific cases.

You need it when:

- Display image is perfect

- Touch works on the full screen

- No black spots or lines

- Only the glass is cracked

If the LCD or touch is damaged, then full display replacement is required. Read here a clear comparison of front glass vs full display replacement cost to understand which option is cheaper and more suitable for your phone.

Types of OCA Machines Available in India

Understanding machine types is important before buying.

1. Manual OCA Laminating Machine

Best for beginners with low budget.

Pros

- Affordable

- Simple operation

- Good for basic training

Cons

- Slower process

- More manual handling

- Higher chance of dust if not careful

2. Semi-Automatic OCA Machine

Most popular choice for Indian repair shops.

Pros

- Better pressure control

- Faster lamination

- Good balance of cost and performance

Cons

- Needs some practice

- Quality depends on operator skill

3. Fully Automatic OCA Machine

Used by high-volume repair centers.

Pros

- Consistent results

- Faster workflow

- Less manual error

Cons

- High cost

- Needs proper power and space

- Not ideal for beginners

Related Machines You May Need

An OCA machine alone is not enough.

Common supporting machines:

- Separator machine (to remove broken glass)

- Autoclave (to remove bubbles)

- Vacuum laminator

- UV lamp (for LOCA cases)

Plan your purchase step by step. Do not buy everything at once unless required.

If you are planning to buy a soldering iron, here is a detailed soldering iron buying guide to help you choose the best one.

Display Types and OCA Compatibility

Different displays behave differently during glass repair.

TFT LCD

- Found in budget cell phones

- Easier to handle

- Lower success rate after repair

IPS LCD

- Common in mid-range smartphones

- Better clarity

- Moderate success rate

Super AMOLED

- Used in premium Android phones

- Very sensitive to heat and pressure

- Needs high-quality OCA machine and skill

A poor machine can easily damage AMOLED panels. Read here the best phones with latest top qualty displays to understand the ctagories of phone screens better.

Key Features to Check Before Buying

This is the most important section.

1. Vacuum Strength

Strong and stable vacuum ensures:

- No air bubbles

- Even bonding

- Better clarity

Weak vacuum leads to repeat work.

2. Pressure Control

Pressure must be:

- Even across the screen

- Adjustable for different sizes

Too much pressure can crack the display.

3. Temperature Stability

Some machines use mild heat.

Check for:

- Accurate temperature control

- Overheating protection

Unstable heat damages displays.

4. Screen Size Support

Make sure the machine supports:

- Small phones

- Large smartphones

- Foldable-size trays if required

5. Build Quality

Look for:

- Strong body

- Good sealing

- Reliable buttons and controls

Lightweight plastic machines often fail early.

6. Power Requirement (India-Specific)

Indian workshops face power issues.

Check:

- Voltage compatibility

- Power backup support

- Surge protection

This avoids sudden breakdowns.

OCA Machine Price Range in India (Practical View)

Prices vary based on quality and automation.

- Entry-level manual machines: lower range

- Semi-automatic machines: mid range

- Fully automatic setups: higher range

Do not choose only by price. Choose by use case.

Beginner Mistakes to Avoid

Many first-time buyers repeat the same mistakes.

Avoid these:

- Buying the cheapest option blindly

- Ignoring after-sales support

- Buying machines without training

- Using low-quality OCA sheets

- Skipping dust-control setup

A cheap machine with no support becomes expensive later.

New vs Used OCA Machine: What’s Better?

New Machine

Pros

- Warranty

- Latest design

- Less risk

Cons

- Higher cost

Used Machine

Pros

- Lower price

- Good for testing business

Cons

- Unknown wear

- No warranty

- Risk of hidden issues

If buying used, test it thoroughly.

Skill Matters More Than the Machine

Many technicians believe buying a machine guarantees success. That is not true.

Good results depend on:

- Glass separation skill

- Dust-free handling

- Correct OCA alignment

- Patience and practice

A skilled hand with a basic machine can outperform an untrained hand with an expensive setup.

Who Should Invest in an OCA Machine?

This investment makes sense if:

- You already do screen replacements

- You get regular glass damage cases

- You want higher profit margins

- You plan long-term growth

If repairs are occasional, outsource glass work first. Most small shop owners outsource glass repair jobs and get them done at highly discounted wholesale rates.

Is OCA Glass Repair Profitable in India?

Yes, when done correctly.

Benefits:

- Lower part cost

- Original display quality retained

- Better customer satisfaction

- Higher margin per repair

But failures increase loss, so training is critical.

Safety and Quality Tips

- Always work in a clean area

- Use quality OCA sheets

- Never rush the process

- Test display fully before delivery

- Educate customers honestly

Quality builds reputation faster than marketing.

Choosing the Right Seller or Supplier

Buy from:

- Trusted tool suppliers

- Sellers offering demos

- Vendors with spare parts support

Avoid unknown sellers with no service backup.

The goal is consistent quality, not speed alone.

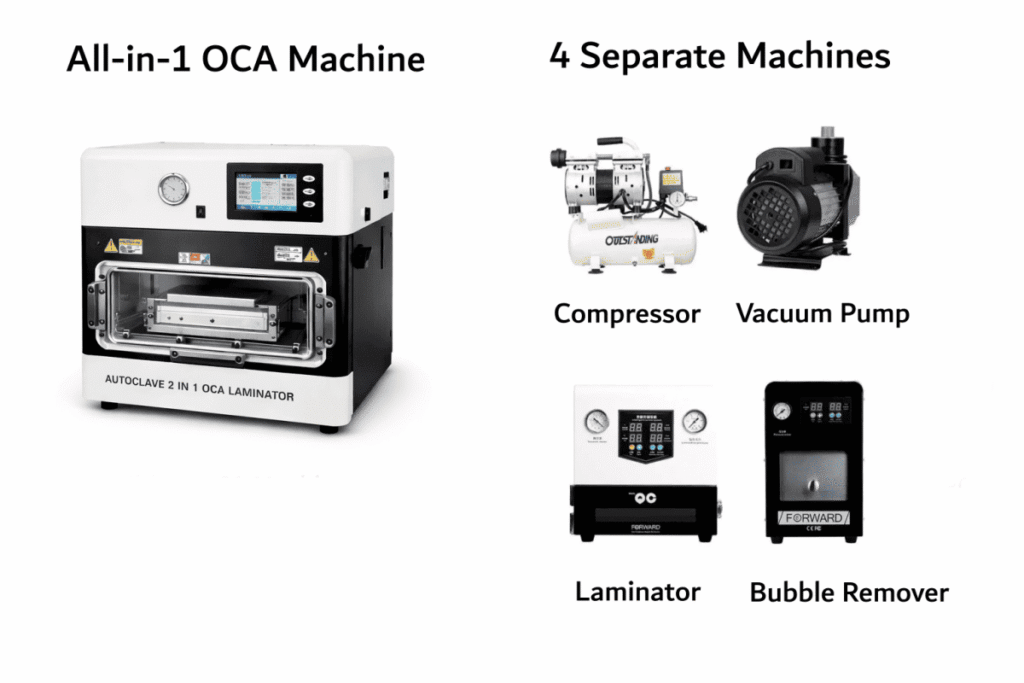

All-in-One vs Four Separate Machines – Pros & Cons

In the 4-Separate machine, the four separate units are:

- Laminating machine / press (laminator) — does the actual OCA bonding.

- Bubble remover / degassing unit — removes micro-bubbles after lamination (sometimes called a degasser or bubble remover).

- Vacuum pump / vacuum laminator — creates a vacuum to avoid air entrapment during bonding.

- Air compressor — supplies clean compressed air for pressure control and pneumatic parts.

Both approaches have real advantages. Pick the one that fits your budget, space, and repair volume.

Option A — All-in-One OCA Machine

Pros

- Space efficient: one unit takes less bench space.

- Simpler workflow: fewer connections and a single control panel.

- Easier to learn: one interface to master.

- Lower initial wiring and setup hassles.

Cons

- Higher repair cost: if one part fails, the whole unit may be down.

- Less flexibility: you cannot upgrade one function independently.

- Higher upfront price for decent quality all-in-one models.

- Often heavier and harder to move.

Best for: small shops, kiosks, beginners, and owners who want a compact, simple setup.

Option B — Four Separate Machines Set (Laminator + Bubble Remover + Vacuum Pump + Compressor)

Pros

- Modular & upgradeable: replace or upgrade one unit without changing others.

- Better redundancy: one failed part doesn’t stop everything.

- Often better performance: dedicated machines can have stronger vacuum pumps or better degassing.

- Cost: It is cheaper an more affordable.

Cons

- More space needed: four units take more bench room.

- Complex setup: more hoses, pipes, and controls to manage.

- Requires more operator skill to coordinate steps.

- Higher cumulative maintenance: more parts to service.

Best for: growing repair shops, high-volume centers, and technicians who value performance and long-term flexibility.

Practical recommendation (for Indian repair shops)

- If you are starting or do low volume: choose a good all-in-one from a reputable brand. It saves space and simplifies training.

- If you expect steady volume or want the best quality for AMOLED: go modular (four separate machines) so you can use stronger vacuum pumps and professional degassing.

- If budget is tight but you plan to grow: start with a reliable laminator + decent vacuum pump. Add bubble remover and compressor later.

Best OCA Machine Brands Available in India

Below is a short, ready-to-add section you can paste into your OCA buying guide. It lists reputable brands and suppliers you’ll actually find in India, explains what each is best for, and points out which ones suit beginners, growing shops, or high-volume centers. I removed nothing from your original list because the brands you gave are available in the Indian market — but I added several more well-known options and reliable suppliers so readers have a useful selection to compare.

Quick tip: always buy from a supplier that offers demonstration, spare parts, and local service — this matters more than brand name alone.

Recommended brands and who they suit

- M-Triangel (M-Triangle) — Popular low-to-mid range OCA laminators (5-in-1 models). Good choice for technicians who want a budget machine that covers laminating plus bubble removal and basic vacuum functions. M-Triangel OCA machines suit beginners who plan to scale later.

- Baba Tools / BABA (Baba OCA Machine) — Widely available full-set kits sold in India (laminator + bubble remover + vacuum pump + compressor). Known for competitive pricing and ready spare kits – Baba Tools is a practical option for small repair shops.

- YMJ (YMJ / YMJ-BABA models) — Reliable 3-in-1 and full-set OCA laminators often offered with faster cycle times. Good mid-range option for shops doing regular glass-only repairs. Check YMJ OCA machine specific model specs for vacuum strength and pump brand.

- Red Sea (RedSea / Red Sea RST) – Indian supplier/manufacturer presence (Mumbai) that sells OCA laminators and related tools. A good pick if you prefer a local supplier who can provide quicker support and demo.

- Best Tools / Best OCA Machines (BST / Best Services) – Marketed as professional OCA laminators with a range of automation levels (BST-series). Best Tool’s OCA machinces suit shops looking to move from semi-automatic to more consistent results. Often comes with warranty and local supply options.

- Sunshine – Known across repair communities for display-related machines and molds. Often used for edge laminating and split-edge jobs; useful if you handle many different phone and tablet models. Good mid-range choice.

- AKT / Made-in-India options (Creative / Local Builders) — There are several Indian-made OCA laminators and “Made in India” models with low price and local support. These can be a smart choice if you need quick spare/technical help and prefer to support local engineering — but confirm build quality and demos first.

- Agni / Agni Wings and other small brands — Sold on marketplaces (Amazon, local dealers) as compact 3-in-1 laminators. Good for testing the business or very low-volume repair work. Validate vacuum strength and seller support before buying.

Which OCA brand for which shop size?

- Beginner / hobbyist / home-based: Agni Wings, small YMJ or entry M-Triangel models.

- Small retail kiosk / repair shop: Baba, YMJ, Sunshine — balanced cost and features with available spares.

- Growing / high-volume shop: Best Tools (BST) series, higher-end M-Triangel models, or remote support from local manufacturers like Red Sea. Consider fully automatic models and autoclave/MDI support.

Here is a full list of mobile phone repairing tools used by professional technicians, with details of their work and prices.

How to choose among these brands (Checklist)

- Ask for a live demo of vacuum strength and bubble removal.

- Confirm spare parts availability in your city or at least in India.

- Check warranty and local service (preferred over lower price).

- Compare cycle time, vacuum pump brand, and power needs

If you wish to build a career in mobile phone repairing, enroll in Prizm Institute’s mobile repairing course in Mumbai and become a certified mobile repair technician in a few months.

Final Summary

Buying the best OCA machine for mobile phone repair in India is not about choosing the most expensive model. It is about matching the machine to your skill level, repair volume, and business plan.

Start with what you can handle. Learn the process. Focus on quality. Upgrade when your workload demands it. With the right approach, an OCA machine can become a strong asset in your mobile repair journey.

Invest wisely. Learn patiently. Grow confidently.