Tag: tips

-

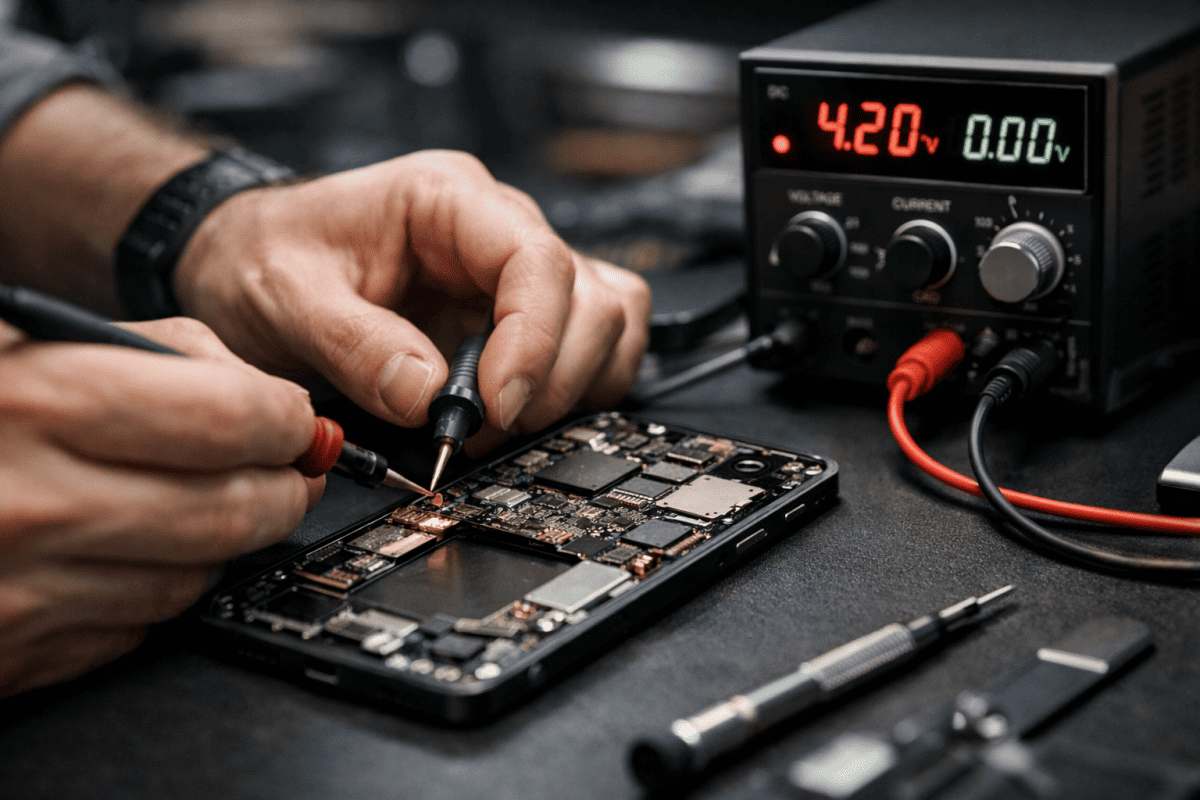

Top 5 Best DC Power Supply Machines for Mobile Phone Repair

Introduction Mobile phone repair has changed a lot over the years. Modern smartphones are compact, powerful, and sensitive to even…

-

How to Make a Slow Old Phone Fast (iPhone & Android Tips)

Introduction A slow phone can be frustrating. Apps take too long to open. The screen freezes. The battery drains faster…

-

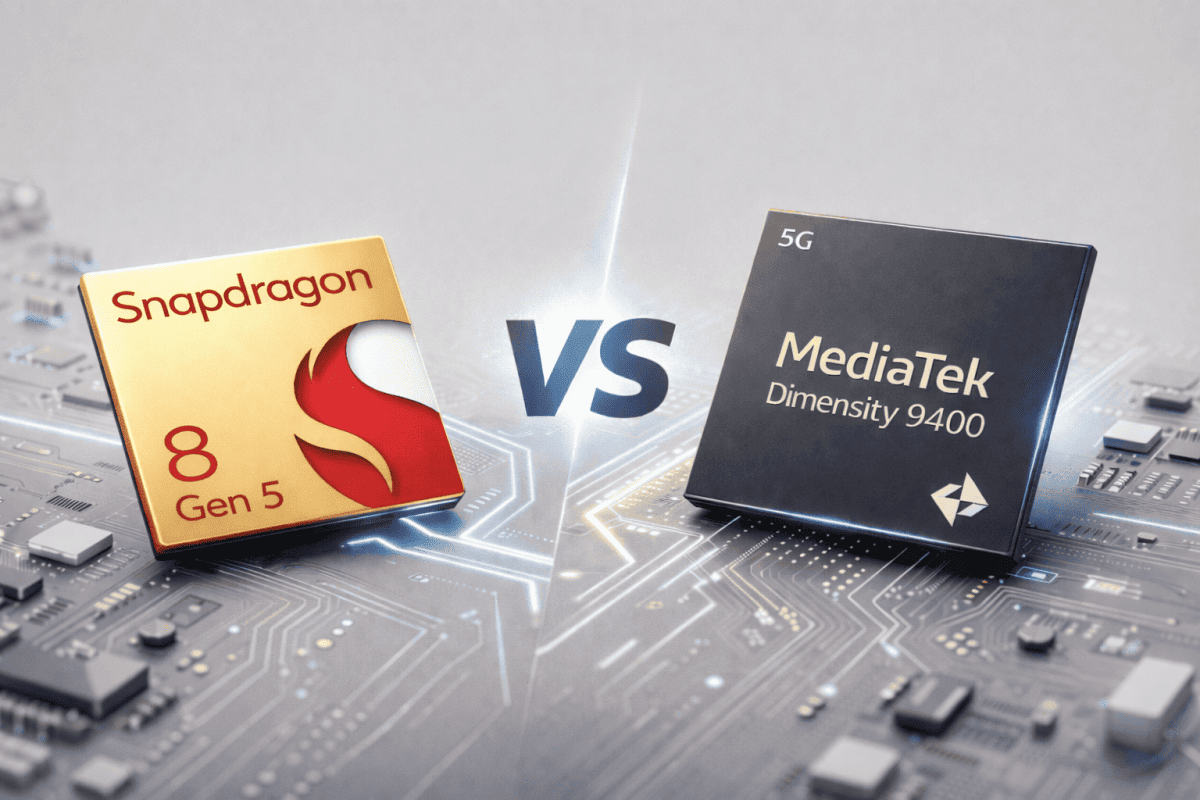

Snapdragon 8 Gen 5 vs Dimensity 9400: Gaming Performance Test

Mobile gaming has moved far beyond casual puzzle titles. Today’s Android phones handle console-level graphics, high refresh rates, and long…

-

Best Latest Gaming Phones under ₹15,000 in India (2026)

Mobile gaming in India has exploded over the last few years, and 2026 is easily the best time ever to…

-

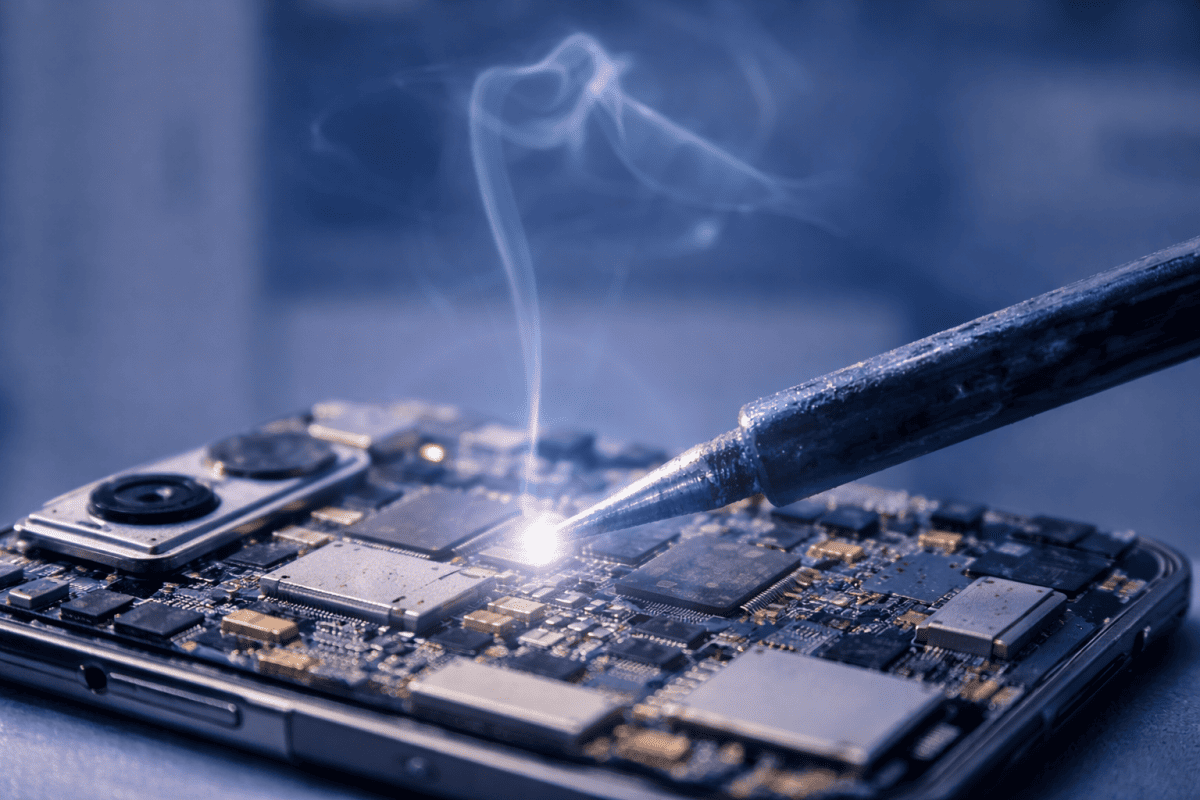

Best Soldering Irons & Stations for Mobile Repair & Electronics In India

Mobile phones and modern electronics are built with tiny components, delicate PCBs, and heat-sensitive parts. Whether you are repairing an…

-

Common Mobile Repairing Terms, Jargon & Full Forms You Must Know

Mobile repairing is a practical skill with growing demand across India and globally. Whether you plan to join a course,…

-

10 Reasons Your Phone Internet Is Slow (And How to Fix It)

A slow internet connection on your phone can be frustrating. Pages take too long to load. Videos keep buffering. Messages…

-

10+ Working Secret Codes & Hidden Tricks for Apple iPhones

Apple iPhones are known for simplicity, security, and smooth performance. But behind the clean interface of iOS, there are hidden…

-

How To Make Your Android Phone Run As Fast As A Ferrari

A slow phone can ruin your mood. Apps open late. The screen stutters. Games lag. Even basic scrolling feels heavy.…

-

8 Common Smartphone Fast Charging Myths Busted

Fast charging has changed how we use our smartphones. Today, a mobile phone can charge from low battery to usable…