A hot air rework station is one of the most important tools in modern mobile repair. Whether you work on Android phones, iPhones, or other smartphones, board-level repair is almost impossible without controlled hot air. From IC removal to micro soldering, this tool decides the quality, safety, and success rate of your work.

In India, many beginners and even experienced electronics technicians make mistakes while buying a hot air station. Some buy very cheap units that damage phone PCBs. Others overspend on features they never use. This guide explains how to choose the right hot air rework station for mobile repair, based on real workshop experience and practical needs.

The right tool does not just make work faster—it protects the device you are repairing.

What Is a Hot Air Rework Station?

A hot air rework station is a machine that blows controlled hot air at adjustable temperature and airflow. It is used to remove and solder electronic components on a smartphone motherboard or PCB. It is also used in repairing other electronic gadgets, appliances and devices.

In repair shops, it is also called:

- Hot air gun

- Hot air blower

- SMD rework station

- IC blower

Unlike a normal heat gun, a rework station gives precise temperature control, which is critical for mobile phone repair.

Why Mobile Phone Repair Technicians Need It

Modern smartphones use tiny components packed tightly on the board. Soldering irons alone are not enough. If you are planning to buy a soldering iron, here is a comprehensive soldering iron buying guide to help you choose the best one for your needs.

A hot air rework station is used for:

- IC removal and refitting

- CPU and other IC heating (advanced level)

- Connector replacement

- IC Reballing

- Shield removal

- Reflow and desoldering

Without proper hot air control, you risk damaging the device permanently.

Who Should Buy a Hot Air Rework Station?

This tool is useful for:

- Mobile repair beginners learning board work

- Repair shop owners upgrading services

- Advanced technicians doing micro soldering

This rework station buying guide will explain you all the details. If you only do screen or battery replacement, you may not need it immediately. But for serious mobile repair, it becomes essential. Here is a complete list of mobile phone repair tools with prices you should have if you are planning to start you own mobile repairing shop or business.

Types of Hot Air Rework Stations Available in India

Understanding types helps you avoid wrong purchases.

1. Analog Hot Air Stations

These use knobs instead of digital displays.

Pros

- Cheaper

- Adjustable heat and air flow

- Simple design

Cons

- Inaccurate and slightly fluctuating temperature

- Hard to repeat results

2. Digital Hot Air Rework Stations

Pros

- Digital temperature display

- Adjustable air flow with auto cut

- Stable heating

Cons

- Quality varies by brand

- More expensive

3. Integrated Soldering + Hot Air Stations

These combine a soldering iron and hot air unit.

Pros

- Saves space

- Convenient for use

Cons

- If one section fails, both stop

- More expensive

Good for small shops and setups

Key Features to Check Before Buying

This is where most buying decisions should focus.

1. Temperature Accuracy and Stability

A good rework station must:

- Reach set temperature quickly

- Maintain stable heat

- Avoid sudden spikes

Unstable heat can lift pads or damage ICs.

2. Airflow Control

Airflow is as important as temperature.

Look for:

- Smooth airflow adjustment

- No sudden air bursts

- Even air pressure

Too much airflow can blow small components away.

3. Heating Element Quality

Ceramic heating elements are preferred.

They offer:

- Faster heating

- Longer life

- Better temperature consistency

Cheap elements fail quickly.

4. Nozzle Compatibility

The station should support:

- Multiple nozzle sizes

- Easy nozzle replacement

Different IC sizes need different airflow concentration.

5. Handle and Hose Quality

Check:

- Heat-resistant handle

- Flexible hose

- No air leakage

A poor handle makes long repair sessions tiring.

6. Power and Voltage Compatibility (India)

Ensure:

- 220–240V support

- Stable performance during voltage fluctuation

This matters a lot in Indian workshops.

Common Temperature Ranges Used in Mobile Repair

While exact numbers vary by job, technicians generally work within safe ranges.

Typical uses:

- Shield removal: medium heat, low airflow

- IC removal: controlled high heat

- Connector work: moderate heat

Blindly increasing temperature is a common beginner mistake.

Cheap vs Professional Hot Air Stations

Cheap Stations

Pros

- Low price

- Easy availability

Cons

- Poor temperature accuracy

- Short lifespan

- Higher risk of board damage

Often cost more in the long run.

Professional Stations

Pros

- Stable results

- Better safety

- Long-term reliability

Cons

- Higher initial cost

Better suited for serious repair work.

Mistakes to Avoid While Buying

Many technicians regret these mistakes later:

- Choosing only by lowest price

- Ignoring airflow quality

- Skipping after-sales support

- Not checking spare part availability

A hot air station is not a one-time-use tool. Support matters.

New vs Used Hot Air Rework Station

Buying New

Pros

- Warranty

- Latest design

- No hidden issues

Cons

- Higher cost

Buying Used

Pros

- Lower price

Cons

- Unknown heating accuracy

- Short remaining life

- No warranty

If buying used, test temperature stability carefully.

Safety Tips Every Technician Should Follow

- Always use heat-resistant tape

- Protect nearby components

- Avoid overheating the PCB

- Practice on dead boards first

- Keep the workspace ventilated

Skill grows faster when safety becomes a habit, not an afterthought.

You must follow several additional soldering iron and rework station safety guidelines to prevent damage and avoid any unexpected incidents.

How Skill Matters More Than Brand

Many beginners believe a costly station guarantees success. It does not.

Good repair depends on:

- Understanding heat flow

- Controlling airflow

- Knowing when to stop heating

- Practicing on scrap boards

A mid-range station in skilled hands performs better than a premium station used carelessly. Here is a nice tutorial on how to use a hot air rework station for both hobbyists and professionals.

Is It Worth the Investment in India?

Yes, if you plan to:

- Offer motherboard repair

- Increase service value

- Reduce outsourcing

- Grow long-term

Board-level repair brings higher margins and customer trust.

Maintenance and Care Tips

- Clean nozzles regularly

- Never drop the handle on the floor

- Switch off after every 3 minutes or when not in use

- Avoid bending the hose

- Do not block air intake

- Let the unit cool before switching off

Simple care increases machine life significantly.

🔧 Best SMD Rework Station Brands for Mobile Repair

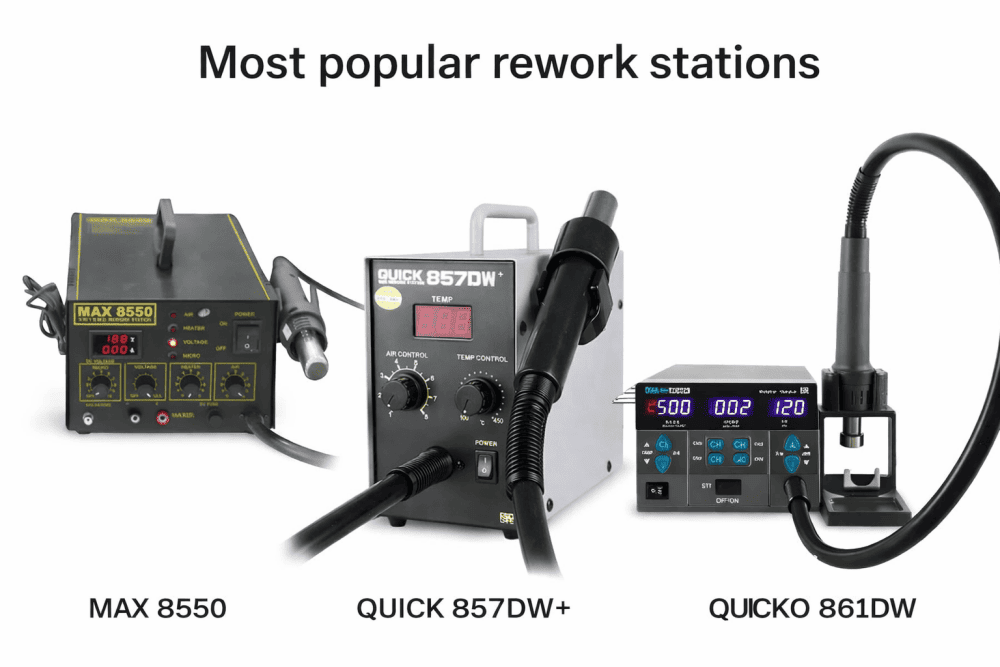

Choosing the right brand and model matters a lot when you are investing in an SMD hot air rework station. Some brands are known for durability and heavy-duty performance, while others focus on specific repair needs like eMMC-level work or budget-friendly options.

A high-quality station gives you stable heat and airflow, which directly affects your success in delicate board-level jobs.

Here are the recommended brands and what they are best at:

⭐ MAX (Heavy-Duty / All-Around Performance)

MAX is widely considered one of the strongest and most reliable brands for SMD hot air stations in mobile repair in India. It offers stable temperature control, strong airflow, and rugged build quality.

- Best for: Beginners, heavy-duty shop use, everyday IC removal and soldering

- Why choose it: Long service life, strong components, reliable heat control

- Cost: Rs 3,100 for Max 850 model

MAX is a go-to choice if you want a station that lasts and handles a wide variety of repair tasks without frequent breakdowns.

🔥 Quick (Best for eMMC & Precision Work)

Quick is another respected name in the electronics repair world. Their hot air stations are especially known for precision and fine control, which makes them excellent for eMMC, CPU, and small IC tasks on mobile phone motherboards.

- Best for: eMMC level mobile repairing, power IC work, fine soldering jobs

- Why choose it: Accurate temperature control, smooth airflow, professional results

- Cost: Rs 5,300 for Quick 857D OG model

If your repair work often involves ICs, other chips, or logic board rework, Quick is the best and durable option..

🔨 Sugon

Sugon offers mid-range hot air rework stations that balance price and reliability. They are popular among technicians who want a solid performance without overspending.

- Best for: Daily shop use, standard SMD & BGA repair work

- Why choose it: Consistent heat control and airflow for most repair jobs

- Cost: ₹8,000–₹12,000+ for different models

Sugon stands out as a reliable choice for technicians building up from beginner to intermediate repair tasks.

💪 Soldron

Soldron produces trustworthy hot air units that are often chosen for stable heat and durability. They also tend to have good spare part availability.

- Best for: General PCB and mobile repair

- Why choose it: Stable performance, easy spares, durable build

- Cost: ₹7,000–₹15,000+ for different models

For many other electronic devices repair centers, Soldron hits the sweet spot between performance and long-term service support.

📉 Budget-Friendly & Local Brands

If you are just starting and need a cost-effective option, there are reliable builds from brands like:

- MAX Pamma

- China/Delhi-made brands / local workshop units

These models are usually:

- Cheaper to buy

- Easy to replace if anything goes wrong

- Cost: ₹1,200 to ₹1,800 for different models

Pros: Low initial cost, good for learning

Cons: Not as precise or durable as premium brands

These budget stations are great for beginners who are still learning board work and want to practice without spending too much.

There is one more type – infrared rework station. An infrared rework station uses infrared heat waves instead of a hot air stream to heat components on a PCB. This method delivers gentler, more uniform heating that is particularly useful for larger chips or boards sensitive to direct hot air, though it’s typically more expensive and specialized than standard hot air systems.

If you wish to learn mobile phone repairing yourself, you are most welcome to join Prizm Institute’s mobile repairing course in Mumbai and become a certified technician in a few months.

🧠 Brand Comparison (Quick Overview)

| Brand | Best For | Performance Level | Value |

|---|---|---|---|

| MAX | Heavy shop use, beginners | ⭐⭐⭐⭐ | Excellent |

| Quick | eMMC & precision work | ⭐⭐⭐⭐ | Great |

| Sugon | Daily shop tasks | ⭐⭐⭐ | Good |

| Soldron | Stable heat & service support | ⭐⭐⭐ | Good |

| MAX Pamma / Delhi brands | Budget / learning | ⭐⭐ | Value |

🛠 Pro Tip Before You Buy

- Always check after-sales support and spare part availability in your city.

- Prefer brands with digital control and adjustable airflow for mobile repair.

- Reliable heat stability matters more than fancy displays.

Final Summary

Buying the best hot air rework station for mobile repair in India is not about choosing the most expensive model. It is about choosing a stable, safe, and practical machine that matches your skill level and repair goals.

Focus on temperature stability, airflow control, build quality, and service support. Start with a reliable digital station, practice patiently, and upgrade as your work grows.

A good hot air station supports your skill. A bad one fights against it.